Tap Clamping Solutions

KSN Holders

Revolutionizing Tool Clamping for Conventional and CNC Machines.

When precision meets innovation, excellence is inevitable. Tuskar proudly presents our exceptional range of KSN Holders – the pinnacle of tool clamping technology. Designed to elevate your machining experience, our KSN Holders redefine accuracy, reliability, and performance, setting new benchmarks in the industry.

Key Features:

Unparalleled Precision

Minimal Run-Out

Versatile Compatibility

Whether you’re working with conventional machines or state-of-the-art CNC marvels, our KSN Holders seamlessly adapt. Their adaptive design accommodates a variety of straight shank tool designs, providing flexibility across different machining processes.

Reliable Process

Balanced Brilliance

Effortless Efficiency

Experience the Future of Tool Clamping:

Our KSN Holders stand as a testament to our commitment to excellence. With a proven track record of empowering industries globally, our tool clamping solutions have become synonymous with precision and innovation.

Whether you’re embarking on intricate CNC machining or embracing the reliability of conventional processes, our KSN Holders are the embodiment of advancement. Elevate your capabilities, amplify your output, and embark on a journey towards machining mastery with our KSN Holders.

Join us in shaping the future of tool clamping technology. Unleash the potential of your machines, one clamping at a time.

Contact us today to explore the possibilities and make precision a part of your every endeavor.

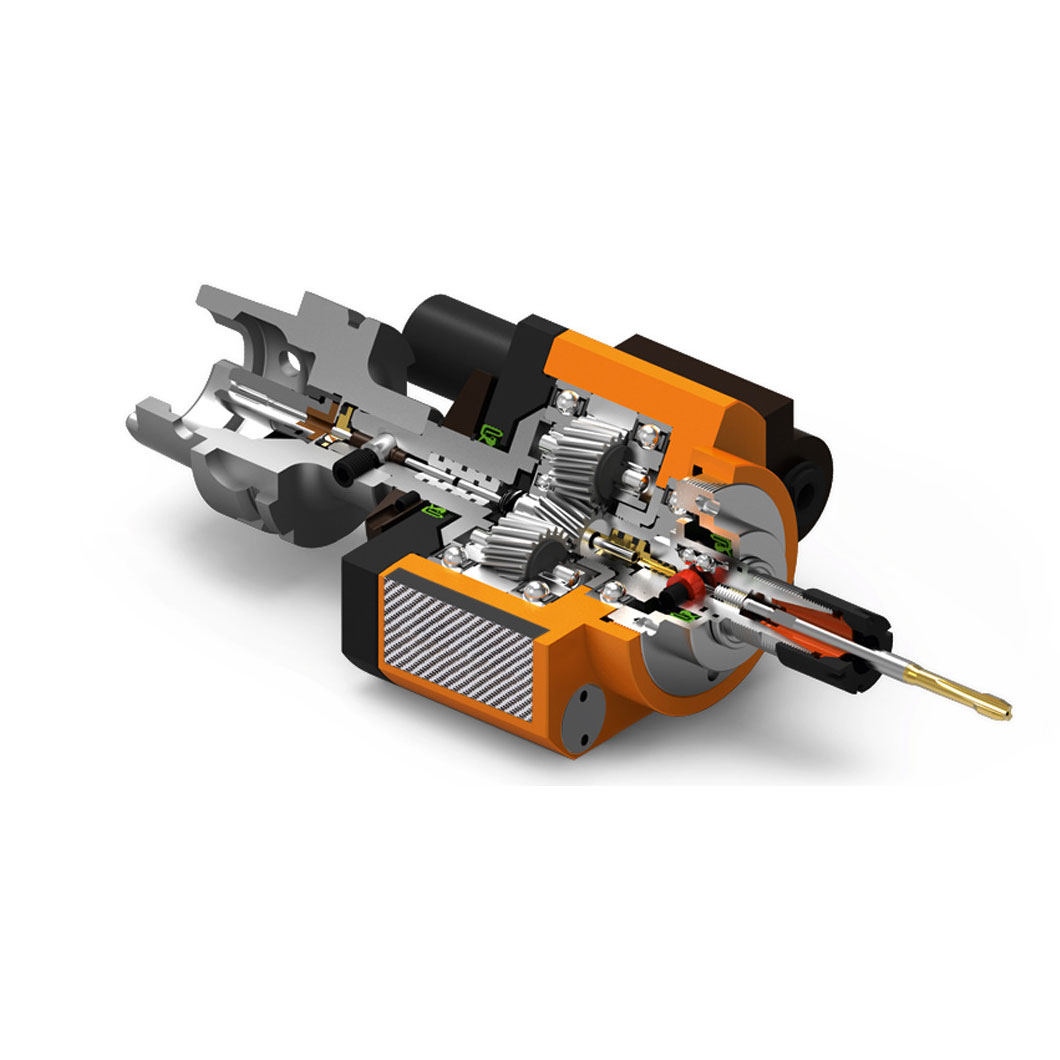

Soft Synchro

Introducing Emuge SoftSynchro™ Tool Holder:

Achieving Perfect Synchronized Tapping

Enhance your machining center’s performance with the cutting-edge Emuge SoftSynchro™ Tool Holder, designed to elevate your tapping operations to a new level of precision and efficiency. As a trusted provider of high-quality manufacturing solutions, we proudly offer Emuge’s state-of-the-art tool holder, engineered to optimize synchronized tapping processes and deliver unparalleled results.

Key Features:

Precision Synchronization

Enhanced Efficiency

Superior Performance

Versatility

Easy Integration

Quality Craftsmanship

Why Choose Emuge?

Industry Leader: Emuge is a renowned name in the manufacturing industry, known for its cutting-edge solutions and commitment to excellence. With the Emuge SoftSynchro™ Tool Holder, you’re accessing top-tier technology that empowers your machining operations.

Expert Support: Backed by our team of machining experts, you can count on us for comprehensive support and guidance. We’re dedicated to helping you optimize your tapping processes and achieve outstanding results.

Unparalleled Innovation: Emuge SoftSynchro™ Tool Holder represents the culmination of years of research, development, and innovation. Stay ahead of the competition with a tool holder that’s designed for the future of machining.

Experience the Emuge difference firsthand and take your tapping operations to new heights. Unlock the potential of synchronized tapping with our cutting-edge SoftSynchro™ Tool Holder. Contact us today to learn more about how this innovative solution can revolutionize your machining processes.

Speed Synchro

- The Speedsynchro collet holder offers significant benefits, enhancing the lifespan of threading tools and substantially reducing cycle times. The collet holder Speedsynchro Modular / NFC incorporates an integrated transmission gear, boosting the machine spindle speed by 4.412 times on the tool side.

- Speedsynchro Modular/NFC Speedsynchro enables higher cutting speeds and reduces thread production time. Meanwhile, the machine spindle can operate at lower rotational speeds, resulting in up to 90% energy savings typically used for spindle acceleration. You benefit from extended tool life for threading tools. All essential operational data can be easily accessed by using an NFC-enabled smartphone, allowing you to stay informed about maintenance schedules and avoid unnecessary expenses.

- Speedsynchro Mini Designed for various series of Brother and Fanuc machine tools with a BT 30 interface, the Speedsynchro Mini boasts a lightweight design, facilitating swift tool changes in the machine tool magazine. Similar to the Speedsynchro Modular, the Speedsynchro Mini also integrates an NFC module to store operating data. Important information, such as the number of threads produced to date and service intervals, can be effortlessly accessed using a smartphone. The required app, available for free on the Google Play Store or the Apple Store, must be installed on a smartphone with an NFC module.

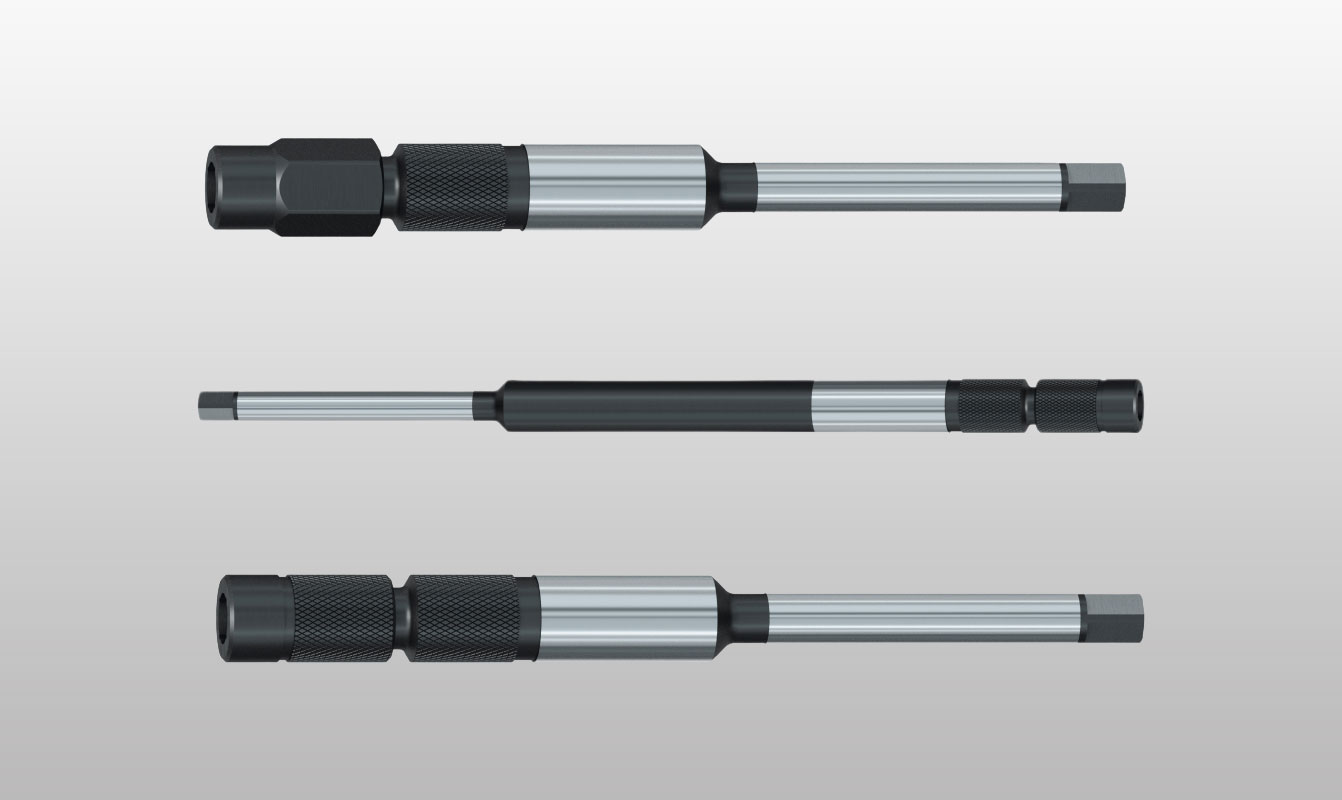

Tap Extensions

When standard tap length falls short, and precision threads are a non-negotiable requirement, look no further than our Tap Extensions. These innovative tools have been meticulously designed to tackle threading challenges where conventional taps cannot reach.

Key Features:

Precision Thread Preparation

Extended Reach

Versatility

Durability

Easy Attachment

Applications

- Aerospace and Aviation: Achieve impeccable threads in intricate components, even in hard-to-reach areas of aircraft and spacecraft.

- Automotive Engineering: Perfect for threading components within engines, transmissions, and chassis where standard taps struggle to reach.

- Medical Device Manufacturing: Ensure the highest standards of thread precision in medical instruments and implants.

- Precision Machinery: Optimize thread quality in complex machinery and equipment, contributing to smoother operations.

- Electronics: Thread delicate components with confidence, even in the most confined spaces within electronic devices.

Why Choose Our Tap Extensions?

Our Tap Extensions stand out as the go-to solution when thread precision cannot be compromised. Backed by cutting-edge design and engineered for reliability, they empower you to achieve flawless threads in every application. Elevate your thread preparation process with Tap Extensions that redefine reach and precision.

Experience the difference today and revolutionize your thread preparation capabilities. Get in touch with us to learn more or place your order.