Milling Solutions

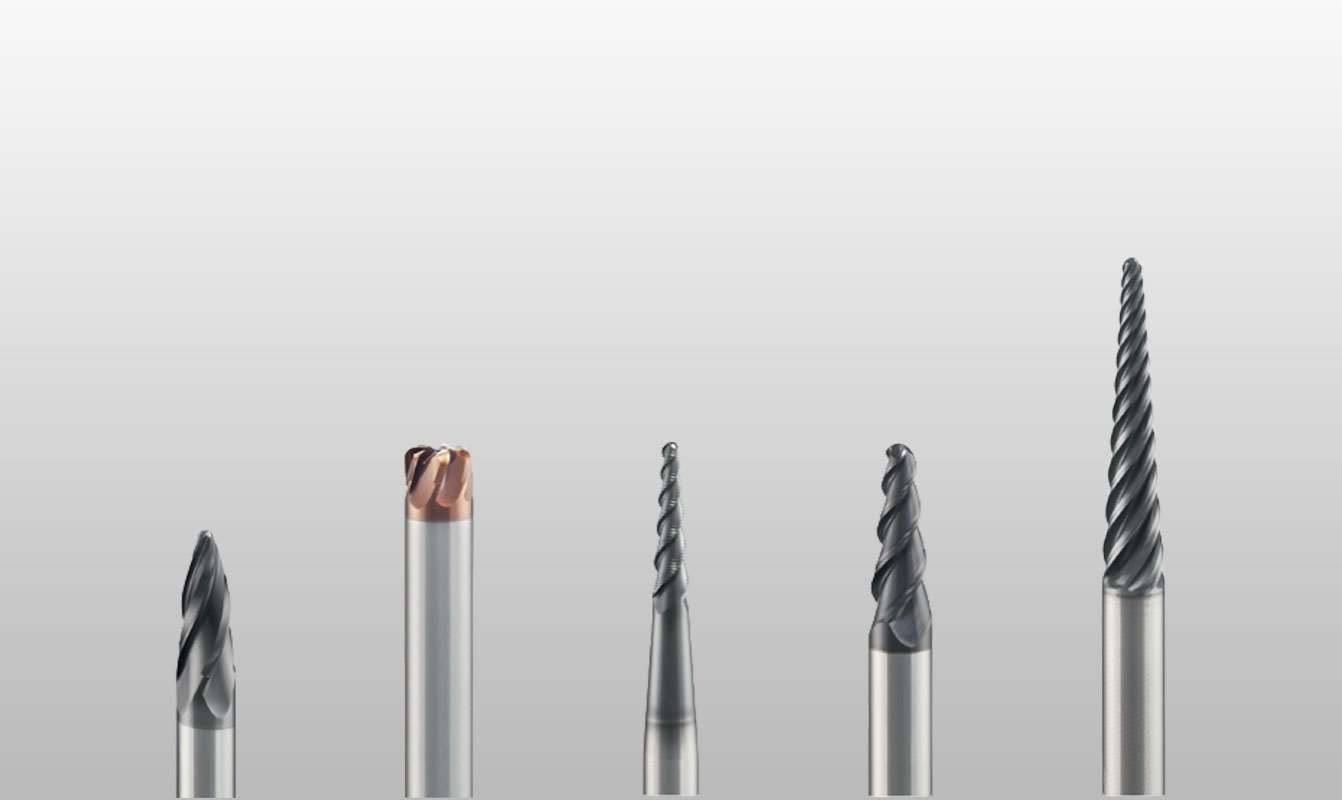

Ball Nose End Mills

Introducing Our High-Performance Ball Nose End Mill Collection!

Unlock Precision and Efficiency in Your Machining Operations

Are you in search of the perfect tool to take your machining capabilities to the next level? Look no further! Our Ball Nose End Mill collection offers cutting-edge technology and exceptional performance to meet your diverse industrial needs.

Precision Engineering

Crafted with utmost precision, our Ball Nose End Mills are designed to deliver impeccable results with every cut. Whether you’re working with metal, plastic, or composite materials, our end mills guarantee superior surface finishes and dimensional accuracy.

The ball-shaped tip of our end mills effortlessly contours and shapes intricate geometries, making them ideal for 3D machining and intricate designs.

Unmatched Versatility

Our versatile range of Ball Nose End Mills can tackle a wide variety of applications, from roughing to finishing, plunging, and profiling. No matter the complexity of your project, our end mills provide the perfect solution.

Designed to excel in both wet and dry cutting conditions, our end mills ensure optimal performance and extended tool life, reducing the need for frequent tool changes and boosting productivity.

Custom Solutions

We believe that every machining challenge deserves a unique solution. Our expert team is ready to collaborate with you to create custom Ball Nose End Mills tailored to your specific requirements. From special coatings to unique geometries, we can help you optimize your machining processes and achieve outstanding results.

Superior Durability

We understand that longevity is key in the world of machining, and that’s why our Ball Nose End Mills are manufactured from premium-grade materials. Each tool undergoes rigorous testing to ensure maximum durability and wear resistance, delivering consistent performance even under heavy loads.

The robust construction of our end mills minimizes chipping and breakage, allowing you to push the limits of your machining operations with confidence.

Ready to elevate your machining game?

Explore our comprehensive range of Ball Nose End Mills today and experience the precision, versatility, and durability that sets us apart. Place your order now and take advantage of our limited-time discounts!

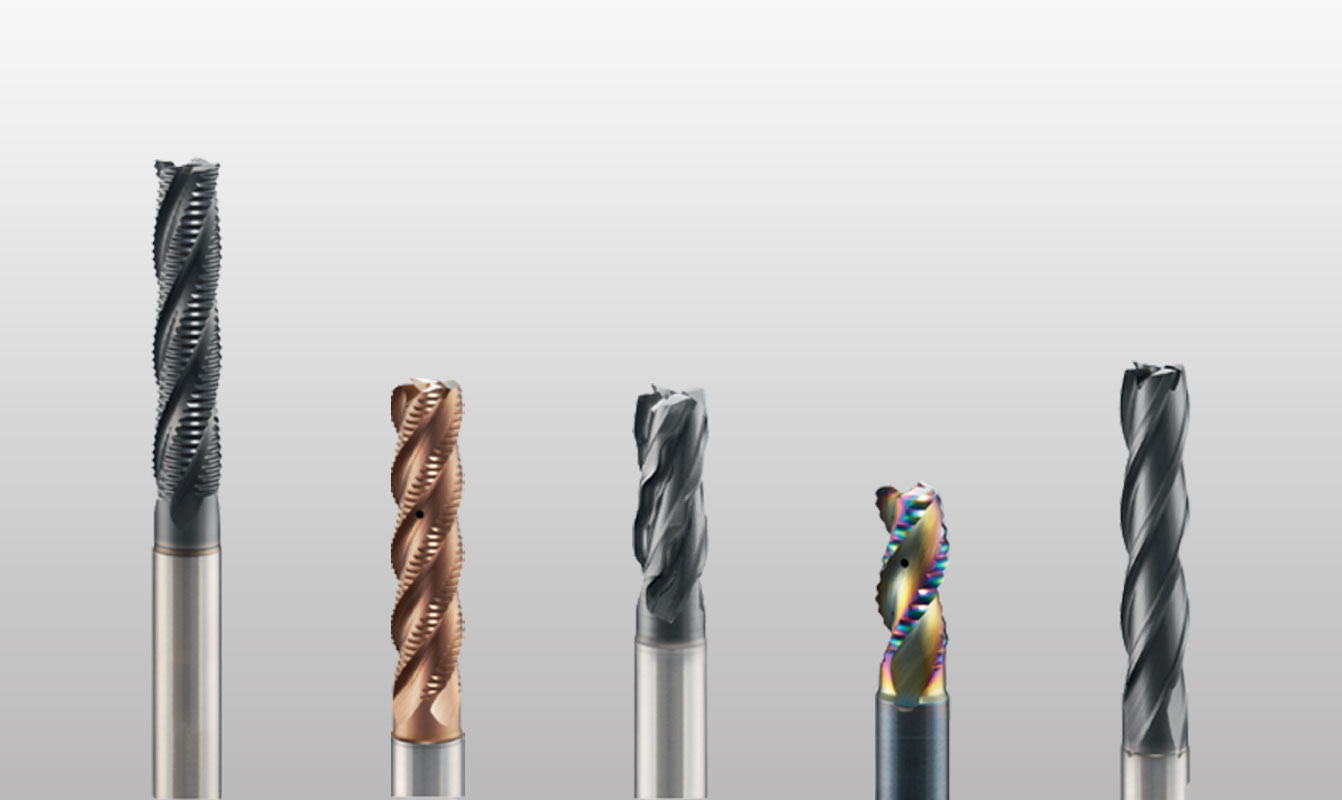

End Mills (HM)

Discover Unrivaled Performance with Our Carbide End Mill Collection!

Experience Precision Machining Like Never Before

Welcome to the world of precision and efficiency! Our Carbide End Mill collection is meticulously engineered to meet the demands of modern machining, offering you unmatched performance and exceptional results.

Unleash Your Potential

Elevate your machining capabilities with our Carbide End Mills, designed to excel in a wide range of applications. Whether you’re tackling hardened steels, exotic alloys, or non-ferrous materials, our end mills deliver consistent and precise cuts every time.

The superior rigidity and strength of carbide ensure minimal deflection, allowing you to achieve intricate details and tight tolerances with ease.

Performance Redefined

Our Carbide End Mills are the epitome of durability and longevity. Engineered from high-grade carbide materials, these tools are heat-resistant and can withstand the most demanding machining conditions.

With advanced coatings that reduce friction and dissipate heat, our end mills maintain their cutting edge, ensuring extended tool life and uninterrupted production.

Versatility at Its Best

From roughing to finishing, slotting to profiling, our Carbide End Mill collection covers the entire spectrum of machining operations. Experience versatility like never before and optimize your workflow with a single, reliable tool.

With specialized geometries and innovative designs, our end mills provide efficient chip evacuation and enhanced performance in various materials.

Tailored to Perfection

Your projects are unique, and so are your machining needs. Our team of experts is ready to collaborate with you to create custom Carbide End Mills tailored to your specific applications. Whether it’s a unique geometry or a specialized coating, we have the solutions to maximize your productivity.

Ready to redefine precision machining?

Dive into our exceptional Carbide End Mill collection today and unlock unparalleled performance and durability.

End Mills (HSS)

Introducing High-Speed Steel (HSS) End Mills: Unleash Precision and Efficiency

Are you ready to take your machining projects to the next level?

Look no further than our premium selection of High-Speed Steel (HSS) End Mills. Designed with cutting-edge technology and precision engineering, these tools are your solution for achieving exceptional performance and accuracy in your milling operations.

Key Features:

Exceptional Durability

Our HSS End Mills are crafted from high-quality high-speed steel, renowned for its outstanding toughness and wear resistance. This ensures a longer tool life, reducing the need for frequent replacements and enhancing cost-effectiveness.

Precision Machining

Achieve impeccable surface finishes and tight tolerances with the superior cutting geometry of our HSS End Mills. Whether you’re working on soft materials or tougher alloys, these tools deliver consistent results with every pass.

Versatility at its Best

Our HSS End Mills are engineered to tackle a wide range of materials, including aluminum, steel, brass, and more. This versatility makes them an essential addition to any machinist’s toolkit, eliminating the need for multiple tool changes.

Optimized Flute Designs

The advanced flute designs of our HSS End Mills facilitate efficient chip evacuation, preventing chip build-up and reducing the risk of tool deflection. This results in smoother cutting action and enhanced overall performance.

Enhanced Heat Resistance

When high temperatures come into play, our HSS End Mills stand strong. Their exceptional heat resistance minimizes thermal distortion, ensuring consistent performance even in demanding applications.

Cost-Effective Solution

The extended tool life and reliability of our HSS End Mills translate into significant cost savings over time. With fewer tool replacements and increased productivity, you can optimize your machining processes and achieve better ROI.

Technical Specifications:

Material: High-Speed Steel (HSS)

Coating: Uncoated (for exceptional heat resistance)

Shank Type: Straight Shank

Flute Design: Variable Helix for efficient chip evacuation

Suitable for: Aluminum, Steel, Brass, and more

Explore Our Range

- Single-End Mills: Ideal for general-purpose milling tasks, these versatile tools are available in various cutting diameters and flute counts to suit your specific requirements.

- Double-End Mills: Maximize efficiency with double-ended designs that allow for two cutting operations without tool changes. This design is perfect for projects that demand quick turnaround times.

- Corner Radius End Mills: Achieve smooth contours and radii with ease using our corner radius end mills. They’re perfect for creating intricate shapes and profiles in your workpiece.

- Roughing End Mills: Tackle tough materials and remove large amounts of material swiftly with our roughing end mills. Their robust construction and aggressive cutting capabilities make them a go-to choice for rough machining.

Elevate your machining game with our premium HSS End Mills. Whether you’re a professional machinist or an enthusiast looking for top-notch results, our tools are designed to exceed your expectations. Explore our diverse range today and experience the difference precision and efficiency can make in your projects.

Revolutionize your machining experience with our HSS End Mills. Discover the perfect balance of durability, precision, and versatility – order now and revolutionize your machining experience!

Tapered End Mills

Elevate Precision with Our Tapered End Mills Collection

Welcome to Tuskar, your destination for cutting-edge machining solutions. Introducing our meticulously crafted Tapered End Mills, designed to redefine precision in your machining processes. Whether you’re a seasoned professional or just embarking on your machining journey, our Tapered End Mills are here to deliver exceptional performance and flawless results.

Unparalleled Design, Unmatched Precision

Smooth Tapered Profiles

Our Tapered End Mills are expertly engineered to create smooth and precise tapered profiles, making them ideal for applications requiring intricate designs and complex geometries.

Optimized Chip Removal

Say goodbye to chip clogging and uneven cutting. Our Tapered End Mills feature strategically designed flutes and helix angles to ensure efficient chip evacuation, reducing downtime and enhancing productivity.

Enhanced Stability

Experience reduced tool deflection and vibration, thanks to our precision-crafted Tapered End Mills. This stability results in higher machining accuracy and surface finish quality.

Versatility Across Materials

Our Tapered End Mills excel across a diverse range of materials:

- Steels: From mild to hardened steels, our Tapered End Mills maintain their edge and longevity, ensuring consistent performance.

- Aluminum: Achieve outstanding surface finish and chip evacuation in aluminum machining, thanks to our specialized flute designs.

- Plastics: Experience clean cuts and minimized melting with our Tapered End Mills, making them perfect for intricate plastic machining.

- Exotics: Conquer challenging materials like titanium, inconel, and more, as our Tapered End Mills demonstrate exceptional heat resistance and wear durability.

Unleash Your Creative Potential

Embrace the freedom to design and create with precision. Our Tapered End Mills offer:

- Fine Detailing: Capture intricate details and delicate contours that demand the utmost precision.

- High-Angle Machining: Explore new design possibilities with our Tapered End Mills’ ability to handle high-angle machining effortlessly.

- Reduced Tool Changes: Complete complex designs with fewer tool changes, thanks to the versatility of our Tapered End Mills.

Experience the Future of Machining:

Elevate your machining game with [Your Company Name]’s Tapered End Mills. Discover how our advanced tools can transform your projects, from rapid prototypes to high-volume production.

Ready to redefine precision and unlock unparalleled creativity? Contact us today to explore our Tapered End Mills collection and take your machining endeavours to the next level.

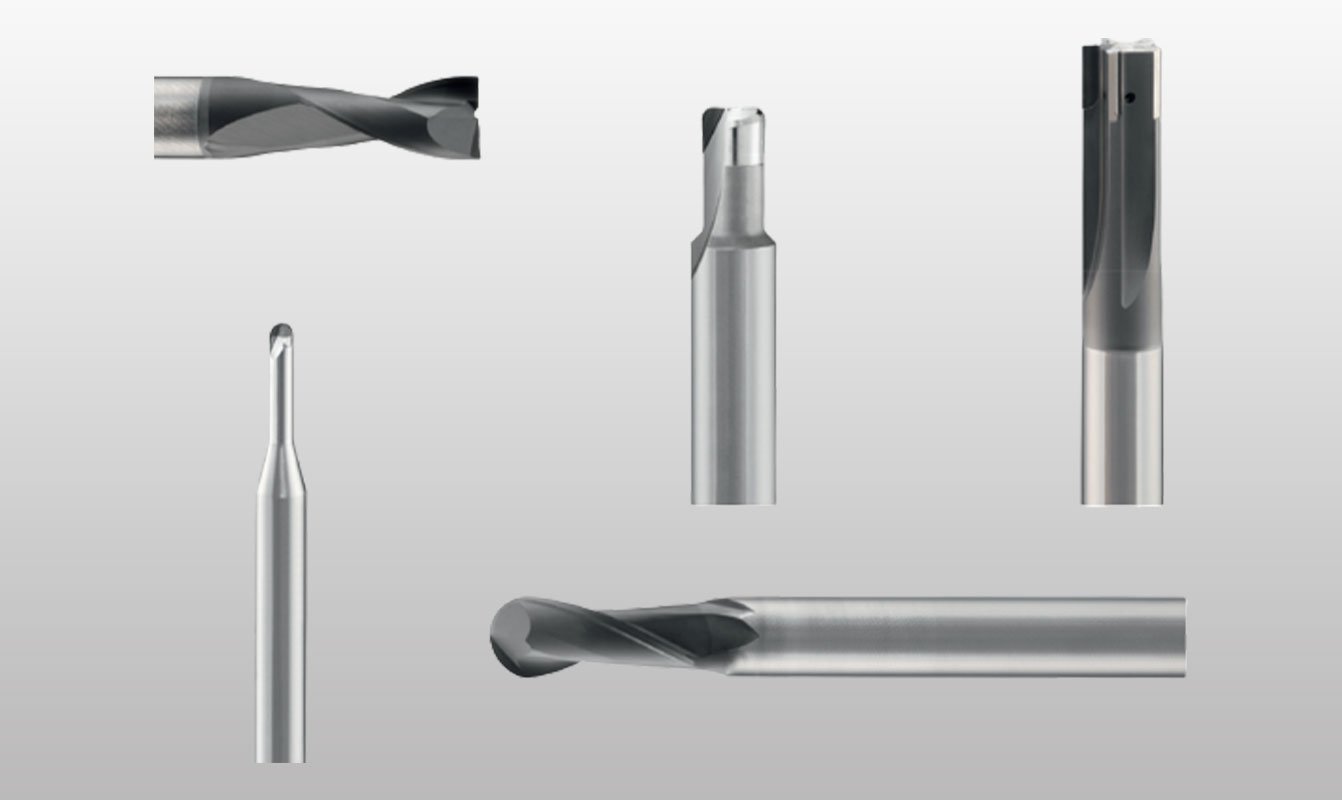

PCD CBN, Diamond Coated End Mills

Introducing Our High-Performance PCD, CBN, and Diamond Coated End Mills

At Tuskar, we pride ourselves on offering cutting-edge solutions for precision machining needs. Our range of Polycrystalline Diamond (PCD), Cubic Boron Nitride (CBN), and Diamond Coated End Mills are designed to elevate your machining processes to new levels of efficiency and quality. Whether you’re working with intricate designs in aerospace, automotive, medical, or any other industry, our advanced tools deliver exceptional results.

Why Choose Our PCD, CBN, and Diamond Coated End Mills?

Unmatched Durability: Our PCD, CBN, and Diamond Coated End Mills are built to last, offering superior wear resistance and extending tool life. This means reduced downtime and increased productivity for your operations.

Precision Redefined: Achieve the finest levels of precision and surface finish with our tools. The ultra-hard materials ensure minimal tool wear, maintaining consistent dimensions and tolerances over extended periods.

Versatile Applications: Whether you’re dealing with non-ferrous materials, abrasive composites, hardened steels, or exotic alloys, our PCD, CBN, and Diamond Coated End Mills excel across a wide range of materials and applications.

Optimized Performance: Experience enhanced chip evacuation and heat dissipation with our specialized designs. This results in smoother cuts, reduced friction, and minimized tool damage.

Cost-Efficiency: While our PCD, CBN, and Diamond Coated End Mills deliver premium performance, their extended tool life ultimately leads to cost savings by reducing the need for frequent tool replacements.

Our Product Range:

PCD End Mills

Crafted from high-quality polycrystalline diamonds, these end mills are perfect for non-ferrous materials and abrasive composites. Enjoy superior wear resistance and precision in your machining processes.

CBN End Mills

When machining hardened steels and superalloys, our Cubic Boron Nitride end mills shine. They offer exceptional hardness, thermal stability, and wear resistance.

Diamond Coated End Mills

Designed for versatility, our Diamond Coated End Mills are suitable for a variety of materials. The diamond coating enhances tool life and promotes efficient cutting.

Unleash the Power of Precision Machining

Discover how our PCD, CBN, and Diamond Coated End Mills can revolutionize your machining operations. From intricate designs to high-volume production, our tools are engineered to deliver consistent, reliable, and exceptional results.

Equip your arsenal with the latest advancements in machining technology. Contact us today to explore our PCD, CBN, and Diamond Coated End Mills and elevate your machining capabilities to unprecedented heights.